All you need are the sheet metal thickness and strain hardening exponent also known as the n value.

N value sheet metal forming.

The shape and placement of the forming limit curve for low carbon steels have been known for decades thanks to the pioneering work of dr.

Of all the mechanical properties determined by a tensile test the plastic strain ratio is the most difficult and requires close attention to detail.

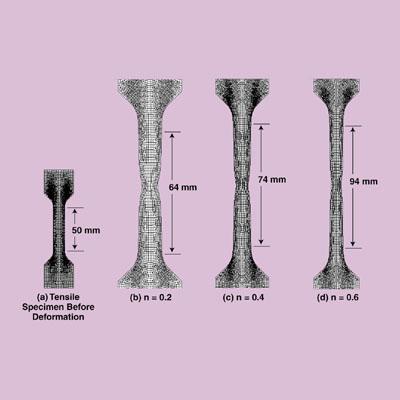

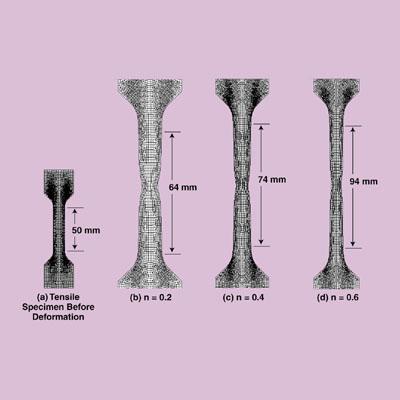

Thus as the n value increases the material s resistance to necking increases and the material can be stretched farther before necking starts.

The strain hardening exponent plays an important role in sheet metal forming.

In order to determine whether a given region has failed a mechanical test is performed.

Sheet metal forming involves forming and cutting operations performed on metal sheets strips and coils.

The effect of the n value in deep drawing is ambiguous.

A forming limit diagram also known as a forming limit curve is used in sheet metal forming for predicting forming behavior of sheet metal.

If thickness is in mm.

The surface area to volume ratio of the starting metal is relatively high.

T co 7wf19j8ofd see it on twitter 3 4 times a year we send out an email on the latest topics related to sheet metal and forming which we find interesting.

The n value describes the hardening increase in strain during plastic deformation up to uniform elongation while the r value describes the vertical anisotropism.

Tools include punch die that are used to deform the sheets.

The larger the n value the more the material can elongate before necking.

Astm e646 standard test method for tensile strain hardening exponents n values of metallic sheet materials is for determining the strain hardening exponent.

Classification of basic sheet forming processes bending deep drawing shearing.

The diagram attempts to provide a graphical description of material failure tests such as a punched dome test.

The r and n values are determined in the tensile test in order to characterize the forming properties.

Astm e517 standard test method for plastic strain ratio r for sheet metal determines the plastic strain ratio.

The strain values that mark the forming limit is called the forming limit curve flc.

It is the ability to maintain thickness as the material is drawn.